The Evolution of Automation in Edible Oil Bottling

From Manual to Automatic Oil Filling: Impact on Production Throughput

Switching from hand operated to automatic systems for bottling edible oils has really boosted how fast factories can produce their goods. Back in the day, workers could only manage around 200 to 300 bottles each hour, and there were all sorts of problems with uneven fills and bad seals on the caps. Now modern filling machines can knock out over 1,500 bottles an hour and keep the amount of oil in each bottle within about half a percent of what it should be. These automatic fillers actually sense changes in the oil's thickness as they work, which cuts down on wasted product that used to happen so often with manual filling. Instead of losing 12 to 15% of the product through mistakes, companies now get much better control over their materials.

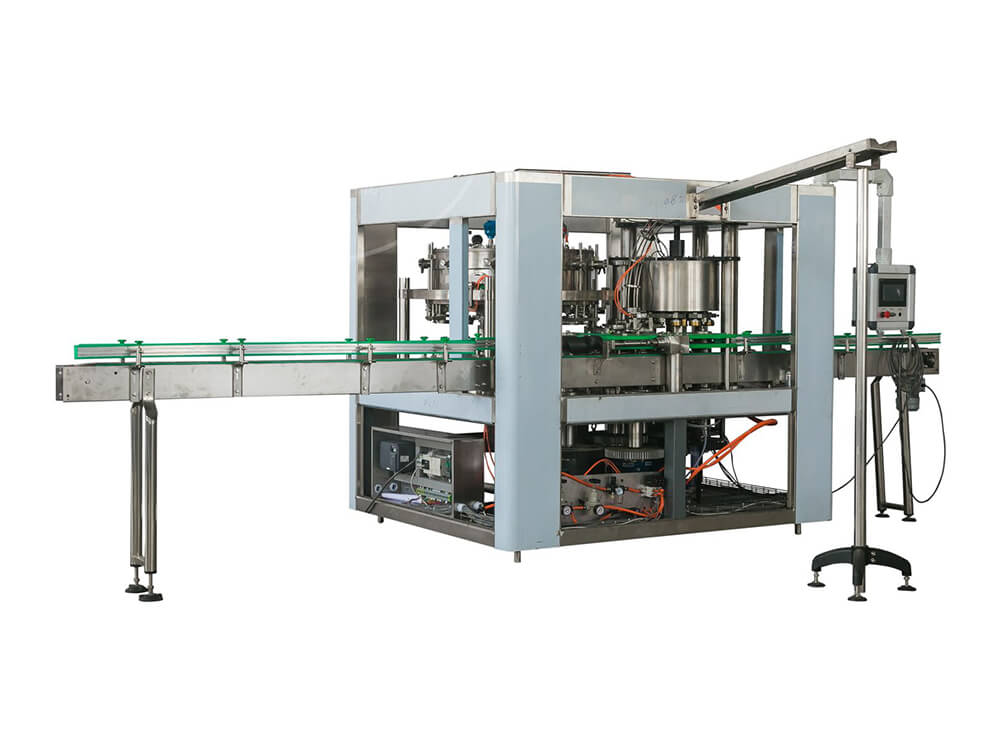

Core Functions of Automatic Blowing, Filling, and Capping Systems

Integrated systems streamline three essential stages:

- Blowing: PET bottles are molded using compressed air for consistent shape and strength

- Filling: Volumetric or gravimetric techniques accurately dispense oils—from light vegetable blends to viscous coconut oil

- Capping: Torque-controlled spindle cappers ensure secure, airtight seals for closures ranging from 28—43mm

This integration cuts changeover times by 70% compared to standalone machines, enabling swift transitions between oil types—such as sunflower to olive oil—in under 15 minutes.

Reducing Labor Costs and Boosting Operational Efficiency Through Automation

When companies implement automation, they often see labor requirements drop somewhere between 60 and 80 percent. What used to take five or seven people working together can now be handled by a single operator. Take palm oil production as an example: batches that once needed eight hours of manual work are completed in around 2.5 hours these days. That means triple the output when demand is at its highest point. The technology doesn't stop there either. With predictive maintenance systems in place, equipment stays running smoothly most of the time. We're talking about around 95 to 97 percent uptime for fully automated systems, which beats the roughly 70 to 75 percent reliability seen in older semi-automatic operations. This kind of improvement makes all the difference in maintaining consistent production levels without constant breakdowns.

Integrated Blowing-Filling-Capping Systems: How They Optimize Oil Packaging

Streamlining Bottling with Synchronized Blowing, Filling, and Capping Stages

Modern combi machines integrate blowing, filling, and capping into a single synchronized line, achieving 23% faster cycle times than conventional setups (2024 Filling Systems Report). By eliminating intermediate transfers, these systems reduce contamination risks and increase throughput by 20%. Key features include:

- Preform heating stations aligned with filler capacity to balance production flow

- Rotary filling valves that adjust flow based on real-time detection of bottle geometry

- Self-calibrating torque-controlled capping heads adaptable to various cap types

PLC-driven controls maintain 97.3% operational efficiency in continuous production environments. Real-time sensors detect bottlenecks and automatically regulate conveyor speeds to keep processes synchronized within ±5 seconds. If capping lags by more than 8 seconds, upstream stages slow down to prevent overflow, while maintenance alerts prioritize corrective actions before failures occur.

Case Study: 99.8% Filling Precision in High-Speed Operations

The new system installed last year for packaging sunflower oil hits an impressive 99.8% accuracy rate when filling those 12,000 bottles every hour. It works with these volumetric piston fillers equipped with inline viscosity compensators that actually adjust how much gets poured based on temperature changes throughout the day. What does this mean? Less wasted product overall compared to older methods we've seen before. The numbers tell the story pretty well too: around 2.1 liters saved per hour just from better control. Plus, they check seals twice during the capping process to meet all those FDA requirements for safety standards in food packaging operations.

Precision, Consistency, and Technology in Automatic Oil Filling

Ensuring High Accuracy and Batch Consistency in Edible Oil Filling

Modern blowing filling capping machines now achieve dosing accuracy around ±0.2% to 0.5%, which cuts down on the 3% to 5% error rates we typically see with manual methods. When manufacturers fill those standard 1 liter bottles, they end up with about 998 to 1002 milliliters each time. That kind of consistency builds customer confidence and keeps everything within legal requirements. These machines come equipped with smart sensors that actually stop the whole line whenever something gets out of alignment. According to some recent studies from Packaging Efficiency Report 2023, this feature alone slashes spillage incidents by nearly 92% compared to older semi-automatic systems. And there's another nice touch too – these machines automatically adjust their flow rates as needed when different batches have varying viscosities. Whether running small test batches of just 500 units or full production runs hitting 5,000 items, the results stay pretty much the same every time.

Key Technologies Enabling Precision in Blowing Filling Capping Machines

Four core innovations drive this level of accuracy:

- Servo-driven piston fillers adjust stroke length in 0.1mm increments, ideal for thick oils like coconut or olive

- Photoelectric sensors detect bottle positions within 0.3mm tolerance before initiating air-blowing cycles

- Anti-drip nozzles with tapered PTFE coatings minimize residue during high-speed capping

- Batch tracking software records fill weights and cap torque values, flagging deviations beyond ±0.5%

Together, these technologies enable leading producers to handle up to 200 bottles/minute with less than 1% downtime, proving automation's ability to merge speed with precision.

Critical Components and System Integration in Oil Bottling Lines

Filling Machine Types (Piston, Gravity, Volumetric, Net Weigh) for Different Oil Viscosities

Blowing-filling-capping systems use specialized filling methods tailored to edible oil viscosity:

| Filling Method | Viscosity Range | Ideal Use Cases | Accuracy |

|---|---|---|---|

| Piston Filling | 500—50,000 cP | Thick oils (palm, coconut) | ±0.5% FS |

| Gravity Filling | 10—1,000 cP | Light oils (soybean, canola) | ±0.3% FS |

| Net Weigh Filling | All viscosities | High-value oils (olive, truffle) | ±0.1% FS |

Volumetric systems achieve ±0.2% precision for medium-viscosity oils like peanut oil (200—800 cP), while net weigh fillers use real-time load-cell feedback to reach 99.9% accuracy for premium products.

Capping Solutions (Snap, Spindle, ROPP): Matching Closures to Bottle Types

Automated capping stations match closure type to container design:

- Snap Caps: Used on PET bottles with tamper-evident seals for 1L—5L cooking oil

- Spindle Cappers: Apply precise 10—25 Nm torque to threaded glass bottles

- ROPP (Roll-On Pilfer-Proof): Deliver aluminum seals for industrial bulk containers

Torque-control systems maintain pressure within ±2%, preventing leaks from under-tightening or container damage from over-tightening.

Integrating Filling, Capping, and Labeling for Seamless Workflow

The PLC control system keeps everything working together smoothly across the production line. Conveyor belts maintain speed within about 0.05 meters per second, while filling nozzles and capping heads coordinate to handle between 600 and 1200 bottles each hour. Downstream photoelectric sensors kick off the labeling process, placing pressure sensitive labels on bottles with almost no misalignment issues – typically less than half a millimeter off target. When all these components work as one integrated system, switching between different products takes around 70 percent less time than traditional manual setups. We've seen this efficiency firsthand in soybean oil bottling operations where precision matters most.

Customization and Future Trends in Blowing Filling Capping Machines

Adapting Machines for Oil Viscosity, Bottle Size, and Production Scale

Today's blowing filling capping machines come with modular setups that handle everything from light sunflower oil at around 35 cP right up to thick peanut oil which can reach over 150 cP. The best part? These hybrid systems actually mix piston mechanisms with volumetric tech so they stay pretty accurate too, keeping within about half a percent error no matter what kind of oil is running through them. What really makes these machines stand out though are those interchangeable molds and capping heads. Switching production from small 250 ml PET bottles to large 5 liter jerry cans takes less than 15 minutes now. That means manufacturers save roughly three quarters of their time during equipment changes compared to older fixed system models according to recent packaging industry reports.

Robotics, Smart Conveyors, and AI-Driven Predictive Maintenance Trends

The latest six axis cobots with vision guided capping stations are making waves in production lines, slashing the need for manual work down to just 8% of what it used to be. These smart conveyor belts with RFID tags keep everything running smoothly, handling blow fill cap operations at around 400 bottles per minute. What's really impressive is how they cut power consumption too, about 30% less thanks to those variable speed drives. Facilities that implemented predictive maintenance software saw their unexpected downtime drop by nearly half last year according to Industrial Automation Journal reports from 2023. The systems basically listen to motors and watch valves closely, catching problems before they cause major disruptions.

Frequently Asked Questions (FAQ)

What are the benefits of switching from manual to automatic oil filling systems?

Switching from manual to automatic oil filling systems significantly boosts production speed and accuracy. Modern filling machines can produce over 1,500 bottles per hour with minimal errors and reduced product wastage compared to manual methods.

How do automatic systems help in reducing labor costs?

Automatic systems reduce labor requirements by 60 to 80 percent. A single operator can now perform tasks that once required several people, resulting in lower labor costs and increased efficiency.

What are the key components of integrated blowing-filling-capping systems?

Integrated systems streamline blowing, filling, and capping stages. Key components include PET bottle molding, volumetric or gravimetric oil dispensing, and torque-controlled capping to ensure secure seals.

How do these systems ensure high accuracy in oil filling?

Modern systems achieve dosing accuracy within ±0.2% to 0.5% through smart sensors, servo-driven fillers, and other advanced technologies, ensuring consistent product quality.

What trends are shaping the future of blowing-filling-capping machines?

Future trends include the adoption of robotics, smart conveyors, AI-driven predictive maintenance, and modular setups for versatile production, aiming to improve efficiency and reduce downtime.

Table of Contents

- The Evolution of Automation in Edible Oil Bottling

- Integrated Blowing-Filling-Capping Systems: How They Optimize Oil Packaging

- Precision, Consistency, and Technology in Automatic Oil Filling

- Critical Components and System Integration in Oil Bottling Lines

- Customization and Future Trends in Blowing Filling Capping Machines

-

Frequently Asked Questions (FAQ)

- What are the benefits of switching from manual to automatic oil filling systems?

- How do automatic systems help in reducing labor costs?

- What are the key components of integrated blowing-filling-capping systems?

- How do these systems ensure high accuracy in oil filling?

- What trends are shaping the future of blowing-filling-capping machines?