Combi series of automatic blowing machine for New Crown company independently developed products. It has the characteristics of simple and convenient operation, stable and efficient, and high yield. The absorption of foreign advanced high-pressure gas recovery technology, ensure the quality of blowing bottles and save gas consumption by 20%, reduce the investment cost and operation cost of low pressure air compressor.

60%

60%

space than regular production line

30%

30%

Save up to 30% water usage

15%

15%

Save up to 15% electric power usage

20%

20%

Require up to 20% less total investment

Apply to: Fresh juice, mixed milk beverage, milky tea and coffee etc. Products with mature technology and high stability. Save electricity and gas. Power and gas consumption are shown on the panel, be clear at a glance. Remote data maintenance, convenient and efficient. Capacity: 15000-36000B/H(500ml)

Apply to: Water, special water or acid beverage Save materials, significantly cut down use of disinfectant.Guarantee complete cleanliness of preform and bottle. Capacity: 15000-36000B/H(500ml)

Apply to: Mineral water, pure water and so on.Compact design ,small land area required.High output, fast, better product quality.Capacity: 16000-81000B/H (500ml)

Apply to: Mineral water, pure water and so on.Disposable tanks, to assure the water qualityHigh speed blowing and filling, high cost performance.Capacity: 3000-6000B/H (5L-8L) 1500-3000B/H (10-20L)

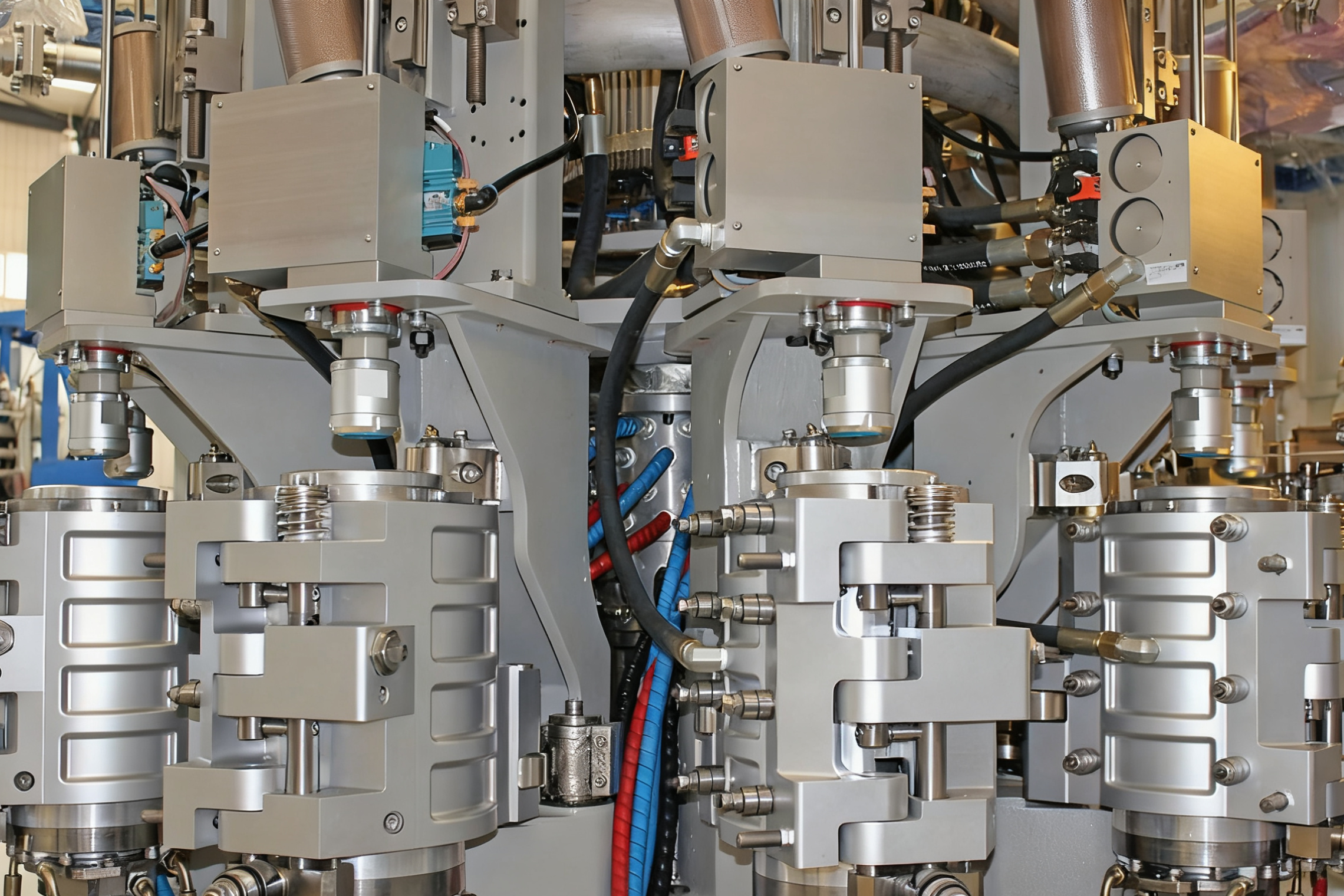

The key components of the bottle blowing machine - the left and right formwork devices are made of high-strength aviation- grade titanium-magnesium alloy (aviation engine material), which is the latest practical invention patent of our company. The big advantages of this technology are excellent tensile, light weight, corrosion resistance. After the application of the new material, the weight of the equivalent product is reduced by more than 60%, and the inertia generated by the same speed rotation is reduced by 60%, which can ensure high-speed and stable operation of the blowing machine.

Compressed air recovery system as standard, saves valuable compressed air 30%.

Cavity pressure instrumentation as standard, it could remove the unqualified bottle, rejection ration is 99.99%

The design of the cam for opening-moulds and mechanical arm is double track, it could deduce the friction between the cam and bearing, the normal life is over 5 years.

The clamp of mechanical arm adopts automatic takeup, to ensure the stability of transmission between the preform and bottle.

Servo tensile system as optional accessories, it adopts the Baumueller motor, Rexroth track. Its accurately control the action of the draw bar could ensure the blown quality of each mold. It could save 20% power meanwhile.

Internet communications platform for commercial installation as optional accessories. To provide the tech solution for bottle blowing machine, the PLC and operation plat can access the Internet through FBOX, network communication, data transmission, cloud

Our professional sales team are waiting for your consultation.