PET Aseptic cold filling refers to the beverage that has been sterilized at high temperature and cooled to room temperature and the package material that has been sterilized and sterilized can be filled and capped in a sterile environment to obtain the drinks that can be preserved for a long time at normal temperature. After nearly 20 years of development, Suzhou new crown PET aseptic cold filling technology has passed the national technical appraisal, and become one of the most powerful companies with real pet aseptic filling technology in China.

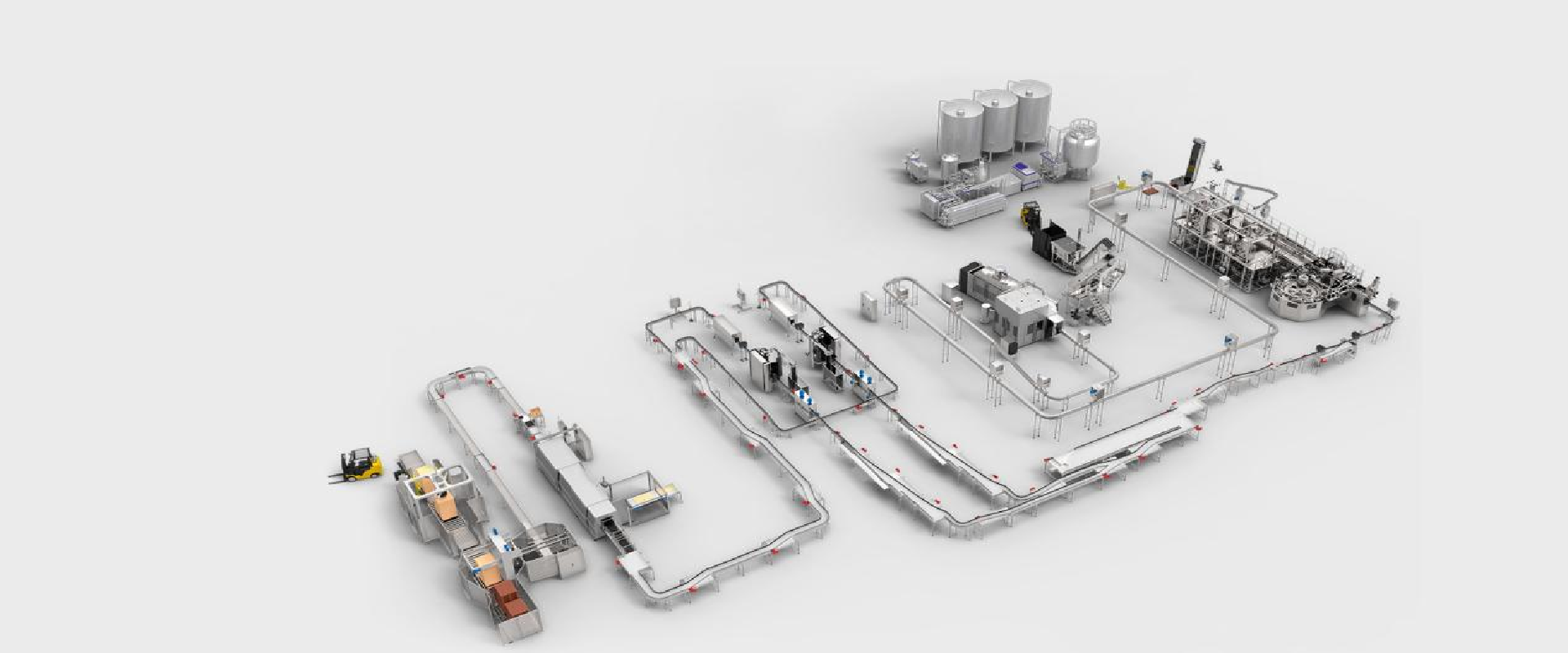

SUZHOU NEW CROWN company has successfully launched aseptic production line with 30000-40000 bottles/hour of new high-speed blowing-filling-capping combi-block and has been popularized and applied. It can satisfy the requirements of customers for the production and filling of various neutral drinks, such as coffee drinks, dairy drinks, herbal tea drinks, plant protein drinks, etc. It can be compatible with the aseptic filling of carbonated / non carbonated drinks which without any preservatives and additives, providing consumers with safe and healthy green drinks. The whole line system is highly automated and controllable, providing localized high-quality equipment and services for the customers who produce middle and high-end drinks. It can not only provide customers with turnkey engineering of whole factory design and installation, but also provide extension services such as aseptic verification, intelligent factory management system and technical training. Fully integrated processing solutions for optimal production performance while ensuring product quality.

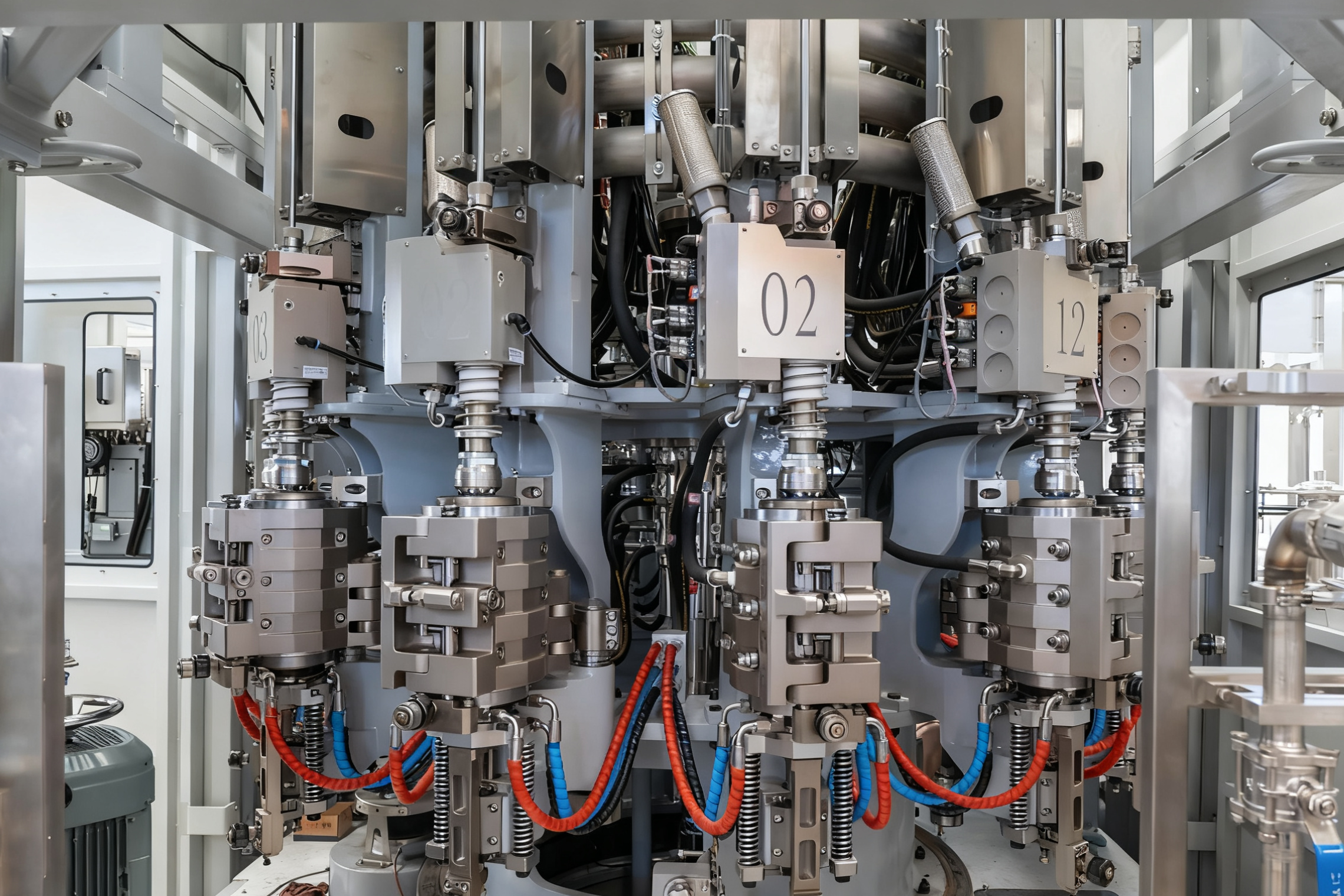

Blowing-filling-capping closed isolation device: when filling machine COP cleaning, the bottle blowing machine is separated by a patented device to avoid corrosion of equipment parts of the bottle blowing machine. Swing dial mechanism: the connection and separation of the two machines are realized by the swing of the middle connecting dial of the blowing-filling-capping. Three-blowing and two-recovery energy-saving technology: pressure difference cascade use, saving compressed air and energy about 40%. Mechanical sealing safeguard technology: The sealing track ensures that the sealing cylinder is raised quickly and absolutely, which is mainly used to ensure the safety of the high-speed blowing machine. Pre-blowing proportional valve control technology: The operation panel controls more precise process guarantees and energy saving measures. 6、Vibration inspection technology: vibration waveform detection at opening and closing mold track , opening and locking mold track, stretching track, bottom mold lifting track etc,to predict whether the working status of each mold number is abnormal.

Spraying, aseptic water rinsing, filling machine and capping unit into an integrated machine. The disinfectant spray is to disinfect the inner and outer surface of the bottle according to the broad-spectrum sterilization performance of the disinfectant. The aseptic water bottle washing machine washes away the disinfectant remaining on the inner of the bottle by washing with sterile water. PET bottles were washed internally and externally, and then drained. The disinfectant solution was effectively washed clean, so that the residual concentration was less than 0.5 ppm. Use sterile water to flush the valve mouth to effectively prevent cross contamination of the bottle mouth ; The lifting guide rod of bottle clamp is protected by bellows to effectively isolate the sterile area from the bacteria area;The filling part is equipped with an automatic false bottle mechanism, which can automatically load false bottles during CIP cleaning and SIP sterilization. The capping machine adopts the independent aseptic servo capping device, grabbing and capping to ensure the finished product rate of capping, adopts the thermal barrier device to effectively isolate the polluted area and the clean area, and adopts the centralized lubrication point for lubrication, easy maintenance.The aseptic isolation device ensures that the static level reaches 100 clean conditions and the dynamic level reaches aseptic state.

Our professional sales team are waiting for your consultation.