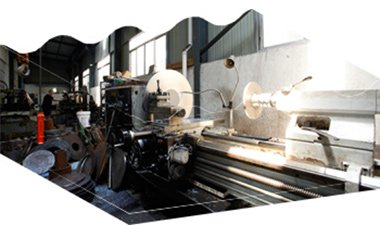

Suzhou New Crown Machine Co., Ltd. was established in 2024. It is a company specializing in beverage production, filing and packaging equipment. Our company has an independent team of engineers, each of whom is a technician with rich experience and can provide professional technical services to the world. Backed by the Suzhou-Chuzhou Inteligent Equipment R&D Center, our company has a 60,000 square meter production base in the Singapore (Suzhou-Chuzhou) High-tech Industrial Park, a national development zone in Chuzhou, Anhui, and a large-scale production base for Combi Block in Langfang, Hebei. Our production workshop is equipped with through-block laser cutting machines, plasma cutting equipment, pentahedron machining center, American Haas processing centers, laser tube cuting machines and other advanced processing equipment, which provide extremely reliable guarantees for the manufacturing accuracy and stability of our products, and create the most competitive automation equipment with unique mechanical design and years of accumulated control essence .

We provide a complete set of inteligent equipment and turnkey engineering services for global liquid product companies. We can provide complete line solutions for production lines of packaging forms such as soft packaging, iron cans, aluminum cans, PET bottles, PE bottles, glass bottles, roof bags, and aseptic cartons. The types of beverages involved

include but are not limited to mineral water, purified water, juice, tea beverages, milk beverages, carbonated beverage production lines 1000-68000 BPH; vinegar, soy sauce, wine production lines 1000-48000 BPH; 3-5 gallon barreled water, production 100-1200 barrels/hour and water treatment plants, canning lines production 1000-42000cph.

In addition, we are very proud of our high-quality Combi Block machines, with a stable output of 18000-68000 bottles/hour.

Years experience

Company employees

Exporting countries

Sqm factory area

After taking order, we will design the complete line according to clients' requests. Main engineer will print out complete machine drawings from bolt and screw.

Before field production, our plant manager and certain workers for the order will gather together and discuss all parts needed to be notice and taken care.

During machine assembling and adjusting, we will get client process report regularly, so that client can get the latest updates of his machinery and adjust request if he needed to.

At first we will prepare all parts needed according to the machine drawings. cutting sheets, polishing bolts, etc.

At end of assembling, we start adjusting the whole machine with clients' liquid and filling vessel. To meet perfect filling status.

During machine assembling and adjusting, we will get client process report regularly, so that client can get the latest updates of his machinery and adjust request if he needed to.

WE LEARN WITH PASSION AND COMMITMENT!

DUBAI BRANCH OFFICE!

INTERNATIONAL TRADE SALES TEAM!

Our professional sales team are waiting for your consultation.