How Blowing Filling Capping Technology Enables Aseptic, Integrated Packaging

Understanding blow-fill-seal technology integration in aseptic packaging

The blow-fill-seal (BFS) method combines making containers, filling them with liquid, and sealing everything all in one go within a sterile environment. This cuts down on the need for extra steps that can introduce contaminants during production. Traditional hot-fill techniques actually damage containers because they rely on such high temperatures, whereas newer BFS machines work at room temperature while still killing germs in the materials. Most big name producers have settled on two main options these days. Some facilities prefer using liquid disinfectants when they need to crank out massive quantities quickly. Others opt for dry sterilization techniques which are better for delicate products that might react badly to chemicals. What makes BFS so valuable is how it meets those strict pharmaceutical cleanliness requirements but still works well across a wide range of applications, whether it's something simple like fruit juice or complex stuff like thick skincare treatments.

Container formation, filling, and sealing in a single continuous process

Modern blow fill cap machines can handle all the packaging steps in just around 15 seconds while operating inside ISO Class 5 cleanrooms. These systems work with closed loop automation that keeps the area at positive pressure and brings down particulates to something like 3,500 per cubic meter or lower, which really helps stop those pesky airborne contaminants from getting anywhere near the product. Since these machines cut down on manual handling by roughly 85% when compared to old fashioned setups with multiple separate machines, they're particularly good for things that react badly to oxygen exposure such as probiotic drinks and similar sensitive formulations.

How BFS reduces contamination risk in liquid filling processes

BFS technology helps prevent contamination in several ways. First, it uses raw materials that are already sterilized before processing. Second, components are handled entirely by machines throughout the production process. And third, everything happens inside environments filtered with HEPA systems to trap airborne contaminants. According to industry reports, microbial contamination drops dramatically when using BFS systems - down to about 0.01% compared with around 1.2% seen on conventional packaging lines. For products like nutritional supplements that don't have high acid content, this kind of control matters a lot because even small amounts of bacteria can affect both product safety and how long it stays good on store shelves.

Compact Design Benefits for Small and Medium-Scale Production Facilities

Space-Saving and Compact Design of BFS Systems for SMEs

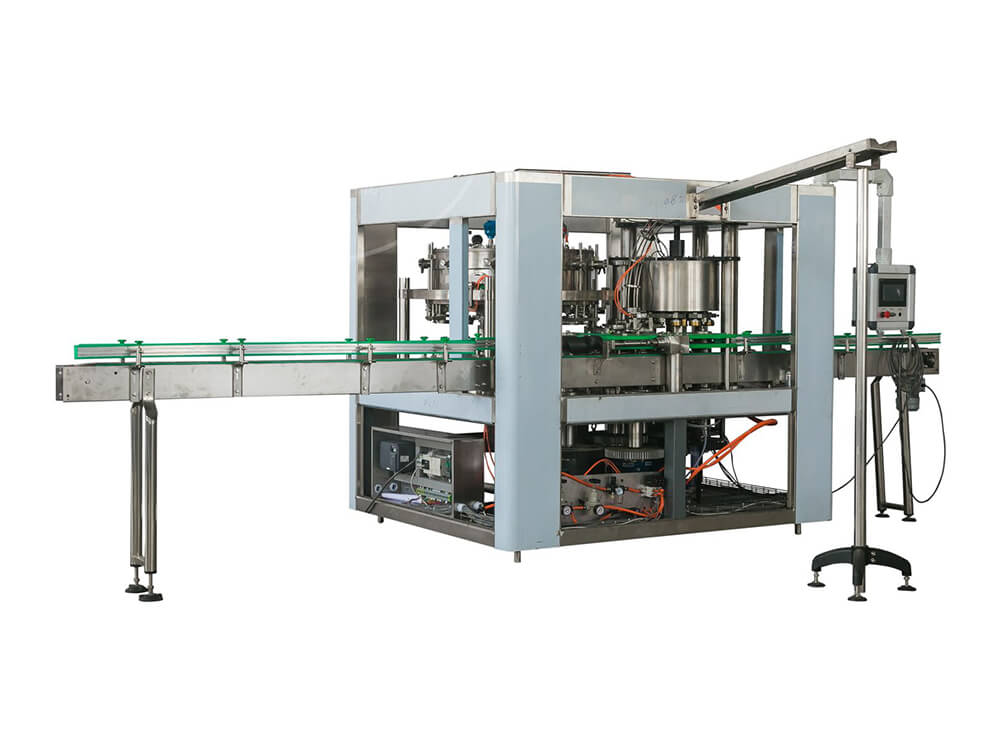

Blow fill seal or BFS systems combine three processes container making, filling liquids, and sealing all within one machine, which eliminates the need for multiple machines and those long conveyor belts we see everywhere else. The way these systems are built vertically and their modular parts actually cut down on factory floor space needs by around 40 percent when compared to older setups, as noted in industry reports from last year. Small businesses and mid-sized companies working out of spaces smaller than ten thousand square feet find this particularly helpful because they can grow their production capacity without having to tear down walls or build additions onto their existing buildings.

Comparative Footprint Analysis: Traditional vs. Integrated Blowing Filling Capping Machines

| Machine Type | Average Footprint | Space Efficiency | Key Features |

|---|---|---|---|

| Traditional Assembly | 200 sq ft | 65% | Separate molding/filling units |

| Integrated BFS System | 120 sq ft | 92% | Unified automation platform |

Integrated BFS systems achieve 35% higher space efficiency by eliminating transfer lines and consolidating automation. Despite the smaller footprint, these systems maintain equivalent output—180–200 bottles per minute—matching traditional configurations while reducing aisle spacing and optimizing workflow layout.

Automation and Contamination Control in Modern Blowing Filling Capping Systems

Automation and Contamination Control in Liquid Filling Systems

Today's BFS systems manage contamination levels under 0.1%, which is quite impressive when compared to older techniques that lag behind by around 87% according to recent PMMI data from 2023. These advanced systems rely on programmable logic controllers, or PLCs for short, to handle several critical processes simultaneously. They control everything from steam sterilization at around 140 degrees Celsius to maintaining fill accuracy within plus or minus half a milliliter, plus they regulate capping torque between three and twelve Newton meters while operating inside ISO Class 5 cleanrooms. What makes these systems so effective? Well, they eliminate those pesky manual handling points where most problems occur. Studies show that roughly 94% of all microbial contamination actually comes from human contact during production. So by taking away those touchpoints, manufacturers can maintain a much higher level of sterility throughout their entire manufacturing run.

Real-Time Monitoring and Closed-Environment Processing

IoT-enabled sensors monitor particulate levels (<0.5µm) and pressure differentials (15–30 Pa) every 50 milliseconds. According to a 2023 technical review, real-time monitoring reduces false rejection rates by 62% compared to batch testing. When environmental deviations occur, the system automatically adjusts sterilization parameters, ensuring uninterrupted compliance during continuous 24/7 operations.

Case Study: Contamination Rate Reduction After BFS Implementation

A pharmaceutical contract manufacturer reduced microbial contamination from 2.4% to 0.3% within six months of installing an automated BFS system (Journal of Aseptic Processing 2024). Key improvements included:

| Metric | Pre-Installation | Post-Installation | Improvement |

|---|---|---|---|

| Batch rejection rate | 8.7% | 1.2% | 86% |

| Changeover time | 45 minutes | 12 minutes | 73% |

| Daily throughput | 12,000 units | 28,500 units | 138% |

The closed-cycle design eliminated 14 manual transfer points previously requiring FDA Class 100 cleanroom protocols, significantly enhancing process reliability.

Operational Efficiency and Cost-Benefit Analysis for Medium-Scale Factories

Throughput Optimization Using Compact Blowing Filling Capping Machines

The compact blowing filling capping machines really boost production rates since they cut down on format changes by around 35 to 50 percent. Factories of moderate size typically see their hourly output jump somewhere between 15 and 25% when there are fewer mechanical transfers happening between the blowing and filling areas according to the Packaging Industry Report for 2023. A real world case study involves a soft drink manufacturer who managed to crank out 1,428 bottles per hour instead of just 1,200 once they installed an integrated BFC system. And interestingly enough, this was accomplished without needing any extra factory space at all.

Maintenance Cost Comparison Between Modular and Integrated Systems

BFS integrated systems get rid of about 60 to 75 percent of those pesky pneumatic parts and conveyors we typically see in modular configurations. According to the Food Processing Maintenance Study from 2024, this change alone can save around eighteen thousand two hundred dollars each year on maintenance for every production line. Modular setups are another story entirely though. They demand constant attention with weekly lubrication tasks and belt tweaking. Meanwhile, these sealed BFC units? Well, they just need filters changed once every three months and motor checks twice a year. The difference adds up over time, significantly cutting down both equipment downtime and the amount of work technicians have to do manually.

ROI Trends in Small to Medium Factories Adopting BFS Technology

The 2024 Manufacturing Tech Report shows that around two thirds of factories that install compact BFC systems get their money back in just over a year. This happens mainly because these systems cut down on contamination waste, which typically saves companies about $42,500 each year, plus they make labor operations much more efficient. For smaller pharmaceutical businesses working with cleanrooms that meet ISO-14644 standards, the return on investment comes in at approximately 2.1 years. That's quite a bit faster than the 3.8 year mark seen with older equipment that gets upgraded rather than replaced. These numbers really highlight why investing in integrated BFS technology makes good financial sense for manufacturers looking at long term gains.

FAQ

What is Blow-Fill-Seal technology?

Blow-Fill-Seal (BFS) technology is a process that involves manufacturing containers, filling them with liquid, and sealing them all in one step within a sterile environment. This method minimizes additional contamination risks.

How does BFS technology reduce contamination risks?

BFS technology reduces contamination by using sterilized raw materials, processing components entirely by machines, and operating in HEPA-filtered environments, which dramatically decreases microbial contamination.

What are the benefits of BFS systems for small and medium-sized enterprises?

BFS systems save space and reduce the need for multiple machines. Their vertically built, modular design can cut down factory floor space requirements by around 40% compared to older setups.

How does BFS technology improve operational efficiency?

BFS technology improves efficiency by eliminating manual handling points, streamlining processes, and using IoT-enabled sensors for real-time monitoring, which helps reduce false rejection rates and improve continuous operations.

Table of Contents

- How Blowing Filling Capping Technology Enables Aseptic, Integrated Packaging

- Compact Design Benefits for Small and Medium-Scale Production Facilities

- Automation and Contamination Control in Modern Blowing Filling Capping Systems

- Operational Efficiency and Cost-Benefit Analysis for Medium-Scale Factories

- FAQ