Aseptic filling equipment is essential for the pharmaceutical and biopharmaceutical sectors, where it guarantees the sterility of injectable drugs, vaccines, and biologics. This specialized machinery—including vial fillers, syringe systems, and isolator technology—executes the precise, automated transfer of sensitive liquid formulations into pre-sterilized containers within a Grade A environment. It is fundamental for processing therapies that cannot undergo terminal sterilization, ensuring patient safety, regulatory compliance, and the integrity of high-value products from monoclonal antibodies to cell and gene therapies.

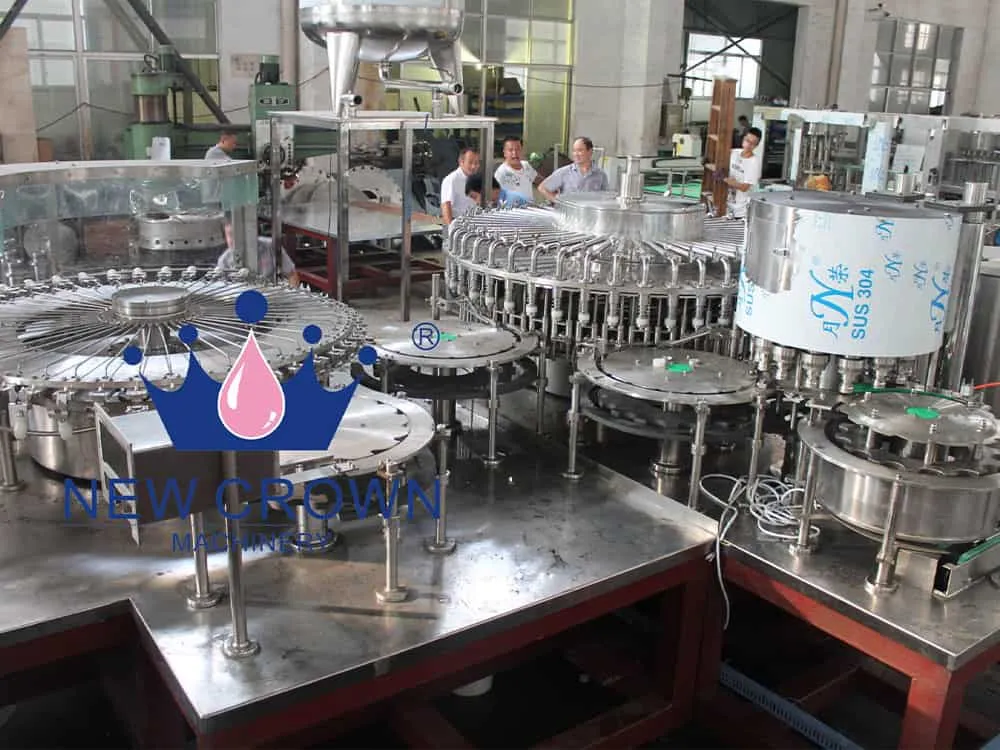

In the food, beverage, and dairy industries, this equipment enables the production of shelf-stable, preservative-free products. Designed to handle liquids like UHT milk, nutritional shakes, and plant-based beverages, it sterilizes containers and products separately before high-speed filling in a closed, aseptic zone. This process extends shelf life without refrigeration, reduces dependency on cold chain logistics, minimizes food waste, and supports the growing demand for clean-label, globally distributed consumer goods.

The application of aseptic filling equipment continues to expand into high-growth markets such as nutraceuticals, cosmetics, and specialty chemicals. These systems accommodate diverse viscosities and container types—from bottles and pouches to cartons—making them ideal for probiotic beverages, protein shakes, preservative-free serums, and sensitive chemical solutions. With advancements in single-use technologies and sustainable packaging compatibility, this equipment offers scalable, flexible, and environmentally conscious manufacturing solutions for innovative brands worldwide.

Our professional sales team are waiting for your consultation.