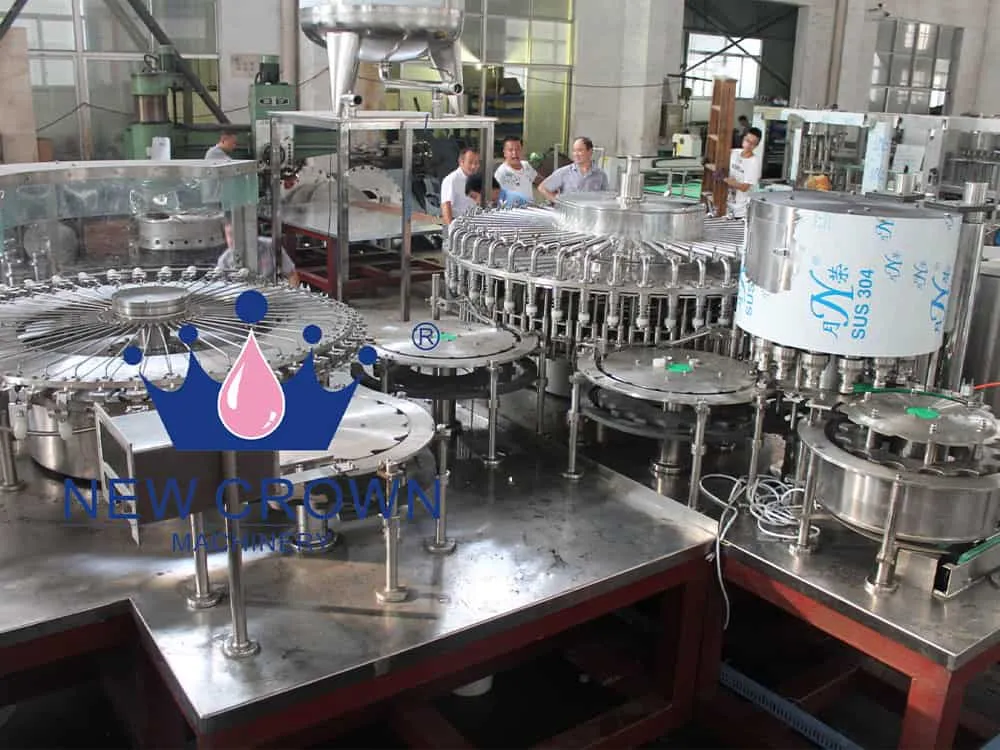

Bottle Water Filling Machine is made as our customer’s need, high filling speed for mineral water, drinking water, can share one machine with several PET bottles. It’s used in producing all kinds mineral water, drinking water, non-gas drink contained in PET bottle. It adopts the normal pressure filling technology.

1. The water filling machine is controlled by PLC with touch-screen as the interface between human and machine.

2. The amount of the drinks in the drink tank can be controlled automatically.

3. The filling and capping will be stopped automatically when there is no bottle.

4. When bottles are cramped wrongly or caps are not avaliable, the machine can be stopped automatically.

5. Horizon swirl air power caps sorting device is used to avoid damagining the surface of caps,and when there is a shortage of caps in the caps storage tank,an alarm signal will be generated and the caps will be fed automatically.

Bottle Water Filling Machine is one of the cleaning equipment in water treatment system basing on the water quality of clients. It is widely applied to the separation, concentration and purification of substances.

All New crown Machines will be packed with high quality plastic film, then put into the wood box increase there is crash and damages.

Our professional sales team are waiting for your consultation.